We’re moving forward rapidly to construct the mechanical element of the mini-plant. Our technical lead, Henrik Falk Poulsen, and inventor, Frank Skjelmose, are working intensely on getting it operational by the 3rd quarter of this year. This project has been well planned and once the mechanical element is complete, the mini-plant will produce board samples.

The availability and capacity of the subcontractors delivering the hardware components is tight, but we are still on target for a completion by the 3rd quarter of 2025.

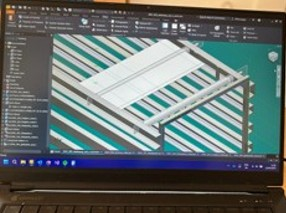

Conveyor

The conveyor for the transport band is under construction.

Adaptors

We’re cutting adapters to be placed between the El-motors and the gearbox.

Mixer

Our mixer equipment is now on-site. Exactly as it sounds, the mixer mixes the recycled paper sludge waste – our raw material – ready to pass to the extruder stage.

Board stacking

In addition to the mechanical plant assembly, we’re also working on the wider logistics including our board stacking system.

Once the mini-plant is in operation mechanically, the next step will be to automate it. Automating will provide valuable ‘ production’ feedback and is a key development step towards establishing the full-scale factory in King’s Lynn. The cost of automating the mini-plant is to be covered by the outstanding seed fundraising.

Besides producing board samples for technical testing and customer engagement, the mini-plant will be a facility for the funders of the full-scale production plant to conduct technical due diligence, providing proof of the production flow. We are already in preliminary discussions with potential funders for this stage of the project.

As a valuable EnviraBoard resource the mini-plant will also be used for R&D to test different sources of raw material / waste, and experiment with board sizing and raw material compositions.