Our Technology

The Technology

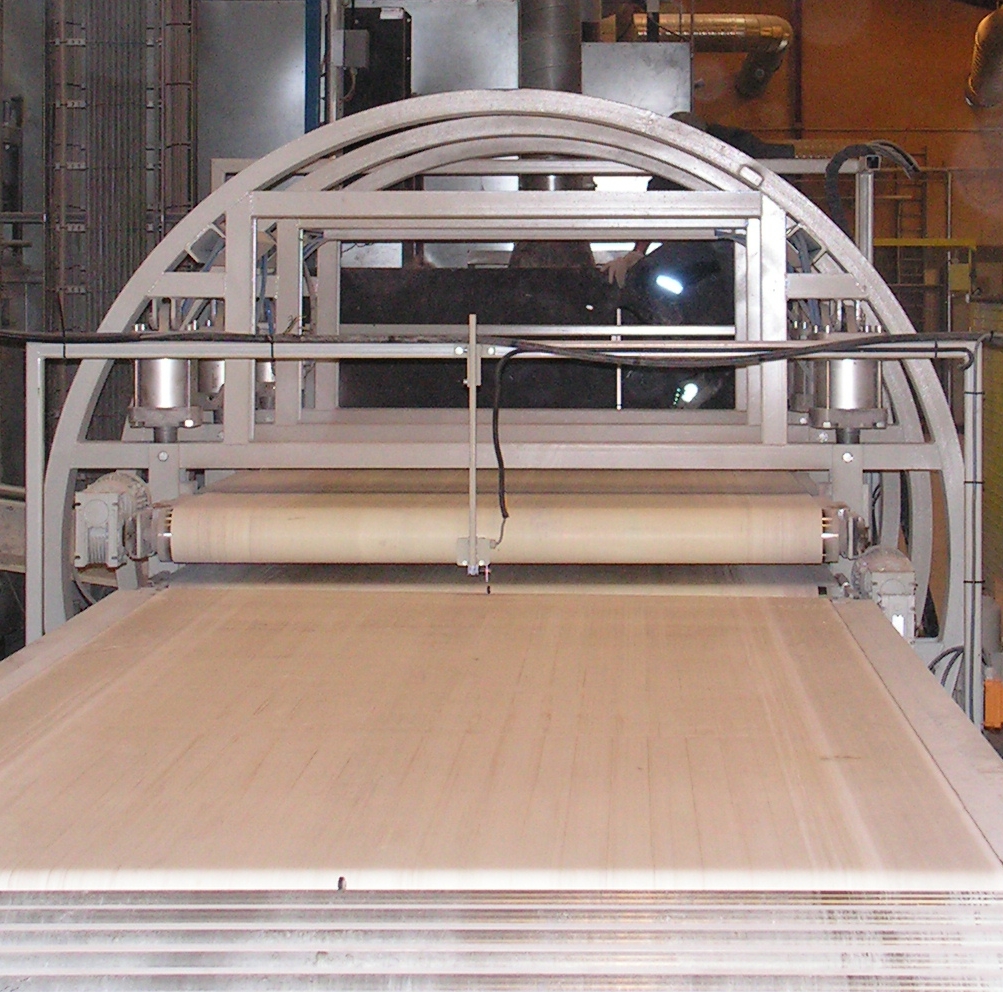

Using proven Danish technology, EnviraBoard provides a very competitive solution for multi-use, adaptable and flexible building boards for the construction industry. The product is environmentally outstanding as it turns paper sludge waste, from recycled paper production, into high-quality and durable building boards.

Perfect for interior applications, they can be used for façade walls, partitioning, ceilings and floors. Following the UK launch we plan to diversify the EnviraBoard range for specialist applications.

Enviraboard Ltd owns the IP of the production technology, having acquired the Danish development company.

The Strategy

The competitive price-quality ratio positions EnviraBoard favourably in the current UK market, with huge international potential. Even before the UK launch, we have already received expressions of interest from distributors in Scandinavia.

We have been working with the Institute for Manufacturing at Cambridge University, who assessed our production line lay-out, researched the UK market for feasible equipment suppliers, and sources of raw material and paper recycling facilities, and as a result we have obtained a letter of intent from Palm Paper for the raw material supply required (the paper sludge waste).

Using leading-edge technology, based on extensive development and production experience in Denmark, Enviraboard is planning to establish a large UK production facility (King’s Lynn) and expand into continental Europe as customer demand increases.

The global construction market (worth US$28bn in 2022) is an opportunity for Enviraboard to establish worldwide production facilities at up to 1,000 paper mills with recycling facilities. It is anticipated that profits of £1-2million+ a year can be achieved for each production facility.

EnviraBoard is aligned with the UN’s Sustainable Development Goals (SDG) 8, 9, 11, 12